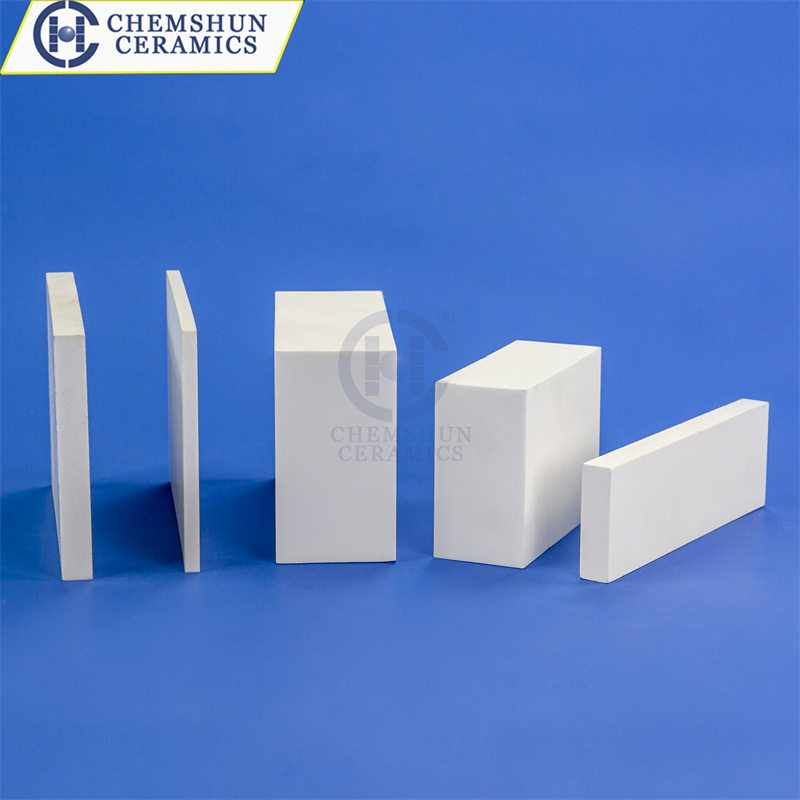

Nganggo Keramik Lining Tile Tahan

Katrangan

Kothak lapisan keramik Chemshun mbantu pangguna nyuda downtime lan nambah produktivitas. kanthi geometri khusus, sawetara potongan mozaik minangka bahan abrasi sing paling apik kanggo divulkanisir ing lembaran karet.Kene kita intorduce sawetara chemshun alumina kothak Keramik kanggo Hopper, chute, siklon, pipe tunks etc informasi peralatan kanggo referensi.

Alumina nganggo ubin liner tanggal teknis

| S. Ora. | Atribut | Unit | Chemshun 92 | Chemshun 92 | Chemshun 95 | Chemshun ZTA |

| 1 | Kandungan alumina | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 3 | Kapadhetan | g/cc | ≥3.60 | ≥3.60 | > 3.65 | ≥4.2 |

| 4 | warna | - | Putih | Putih | Putih | Putih |

| 5 | Penyerapan banyu | % | <0.01 | <0.01 | 0 | 0 |

| 6 | Kekuatan lentur | Mpa | 270 | 300 | 320 | 680 |

| 7 | Kapadhetan Moh | sasmita | 9 | 9 | 9 | 9 |

| 8 | Kekerasan Sumur Batu | HRA | 80 | 85 | 87 | 90 |

| 9 | Kekerasan Vickers (HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 10 | Ketangguhan Patah (Min) | MPa.m1/2 | 3-4 | 3-4 | 3-4 | 4-5 |

| 11 | Kekuwatan kompresif | Mpa | 850 | 850 | 870 | 1500 |

| 12 | Koefisien Ekspansi Termal (25-1000 ℃) | 1x10-6/℃ | 8 | 7.6 | 8.1 | 8.3 |

| 13 | Suhu operasi maksimum | ℃ | 1450 | 1450 | 1500 | 1500 |

Aplikasi ing Industri

| Industri | Sistem peralatan | bagean peralatan |

| semen | Sistem pra-campuran kanggo nabrak kapur lan bahan bakar mentah | Chute, bunker, pulley lagging, discharge cone |

| Sistem pabrik mentah | Feed chute, retaining ring, scraper plate, seal ring, pipeline, bucket guard, cyclone, powder concentrator body, bunker | |

| Sistem pabrik semen | Chute, bunker, roda baling-baling kipas, casing kipas, siklon, saluran bunder, conveyer | |

| Sistem ball mill | Awak knalpot pulverizer lan roda baling-baling, awak konsentrator bubuk, pipa batubara bubuk, saluran udara panas | |

| Sistem sintering | Inlet/outlet bend, wind value plate, cyclone, chute, pipa kolektor debu | |

| Sistem afterheat | Pipa separator lan tembok | |

| baja | Sistem pakan bahan mentah | Hopper, silo |

| Sistem Batching | Nyawiji bunker, nyawiji tong minyak, nyawiji disk, disk pelletizer | |

| Sistem transportasi bahan sintered | Hopper, silo | |

| Sistem Dedusting lan Ash discharge | Pipa dedusting, bend, y-piece | |

| Sistem coking | Coke hopper | |

| Pabrik kacepetan medium | Kerucut, buffle pemisah, pipa outlet, pipa batubara bubuk, kerucut pembakar | |

| gilingan bal | Klasifikasi, pemisah siklon, bend, cangkang jero konsentrator bubuk | |

| Daya termal | Sistem penanganan batubara | Mesin roda ember, hopper batubara, feeder batubara, orifice |

| Sistem ball mill | Pipa pemisah, siku lan kerucut, siku pabrik batu bara lan tabung lurus | |

| Pabrik kacepetan medium | badan pabrik batu bara, buffles pamisahan, conthong, pipa, sikut | |

| Pabrik tiba | Pipa lan sikut batubara sing digiling | |

| Sistem dedusting | Pipa lan sikut Dedusting | |

| Sistem pembuangan abu | Cangkang kipas, pipa | |

| Pelabuhan | Sistem transportasi bahan | Disk lan hopper mesin roda ember, hopper titik transfer, hopper unloader, |

| Peleburan | Sistem transportasi bahan | Measuring hopper, coke hopper, vibrating screen's chute, head valve, Intermediate bin, tail bin |

| Sistem Batching | batch hopper, nyawiji mesin | |

| Sistem pembakaran | Ember awu, tabung kalsin pompa, hopper | |

| Sistem dedusting | Pipa lan sikut Dedusting | |

| Kimia | Sistem transportasi bahan | Hopper, silo |

| Sistem dedusting | Pipa lan sikut Dedusting | |

| peralatan pangolahan | Vibromill liner | |

| Batu bara | Sistem penanganan batubara | Mesin roda ember, hopper batubara, feeder batubara |

| Sistem cuci batu bara | Hidrosiklon | |

| pertambangan | Sistem transportasi bahan | Hopper, silo |

Layanan

Kita nampa pesenan khusus.

Yen sampeyan pengin ngerti informasi produk liyane, hubungi kita lan kita bakal menehi sampeyan produk sing paling cocok lan layanan paling apik!