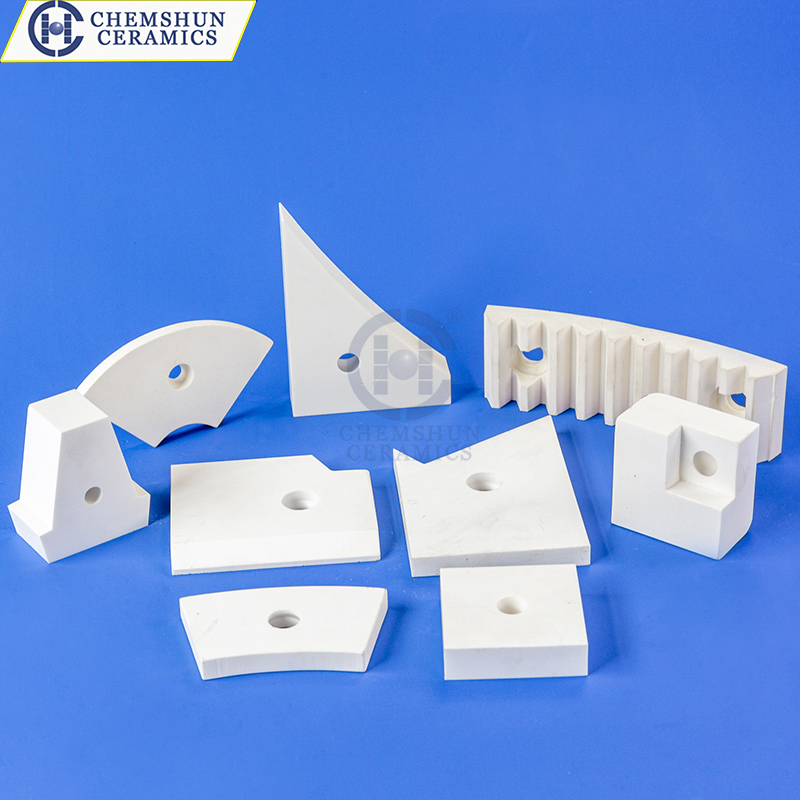

Alumina Keramik Wear Plate kanggo pangopènan industri

Fitur

· Properti tahan korosi sing apik

· Gampang ditangani ukuran lan bobot

· Properti tahan panas sing apik banget

· Properti tahan impact sing apik banget

· Instalasi cepet lan aman

· Biaya produksi lan pangopènan sing luwih murah

Kaluwihan Keramik Chemshun

· Tim teknis profesional kanggo menehi desain CAD

· Tim instalasi profesional kanggo mbayar layanan instalasi

· Proses mapan miturut standar internasional

· Nampa kothak standar lan wis dirancang

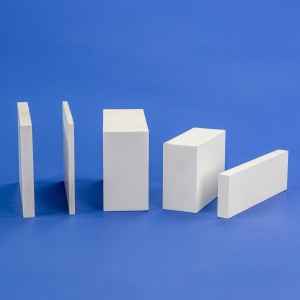

ukuran

| ITEM NO. | PRODUK | LONG x JABUR | KETEBAL | Q'TY PER KOTAK |

| mm | mm | pcs | ||

| 1 | TETELAN KOTAK | 100 x 100 | 6 | 50 |

| 2 | TETELAN KOTAK | 100 x 100 | 12 | 20 |

| 3 | TETELAN KOTAK | 100 x 100 | 15 | 15 |

| 4 | TETELAN KOTAK | 100 x 100 | 25 | 10 |

| 5 | TETELAN KOTAK | 100 x 100 | 50 | 5 |

| 6 | TETELAN KOTAK | 100 x 25 | 6 | 135 |

| 7 | TETELAN KOTAK | 150 x 100 | 6 | 50 |

| 8 | TETELAN KOTAK | 150 x 100 | 12 | 20 |

| 9 | GENTENG KOTAK | 150 x 100 | 12 | 20 |

| 10 | TETELAN KOTAK | 150 x 100 | 15 | 15 |

| 11 | TETELAN KOTAK | 150 x 100 | 25 | 10 |

| 12 | GENTENG KOTAK | 150 x 100 | 25 | 10 |

| 13 | TETELAN KOTAK | 150 x 100 | 50 | 5 |

| 14 | TETELAN KOTAK | 150 x 50 | 12 | 40 |

| 15 | TETELAN KOTAK | 150 x 50 | 25 | 20 |

| 16 | TETELAN KOTAK | 150 x 25 | 6 | 135 |

| 17 | TEMBUNG PIPA | 150 x 31/35 | 12 | 57 |

| 18 | TEMBUNG PIPA | 150 x 39/42 | 12 | 40 |

| 19 | TEMBUNG PIPA | 150 x 50/53 | 12 | 40 |

| 20 | TEMBUNG PIPA | 150 x 45/47 | 12 | 40 |

| 21 | TEMBUNG PIPA | 150 x 27/35 | 25 | 20 |

| 22 | TEMBUNG PIPA | 150 x 35/42 | 25 | 20 |

| 23 | TEMBUNG PIPA | 150 x 47/53 | 25 | 20 |

| 24 | TEMBUNG PIPA | 150 x 43/47 | 25 | 20 |

| 25 | TEMBUNG PIPA | 150 x 43/47 | 50 | 10 |

| 26 | TILE WELDABLE | 100 x 100 | 12 | 20 |

| 27 | TILE WELDABLE | 100 x 100 | 15 | 16 |

| 28 | TILE WELDABLE | 100 x 100 | 25 | 10 |

| 29 | TILE WELDABLE | 100 x 100 | 50 | 5 |

| 30 | TILE WELDABLE | 150 x 100 | 12 | 20 |

| 31 | TILE WELDABLE | 150 x 100 | 15 | 16 |

| 32 | TILE WELDABLE | 150 x 100 | 25 | 10 |

| 33 | TILE WELDABLE | 150 x 100 | 50 | 5 |

Aplikasi ing Industri

| Industri | Sistem peralatan | bagean peralatan |

| semen | Sistem pra-campuran kanggo nabrak kapur lan bahan bakar mentah | Chute, bunker, pulley lagging, discharge cone |

| Sistem pabrik mentah | Feed chute, retaining ring, scraper plate, seal ring, pipeline, bucket guard, cyclone, powder concentrator body, bunker | |

| Sistem pabrik semen | Chute, bunker, roda baling-baling kipas, casing kipas, siklon, saluran bunder, conveyer | |

| Sistem ball mill | Awak knalpot pulverizer lan roda baling-baling, awak konsentrator bubuk, pipa batubara bubuk, saluran udara panas | |

| Sistem sintering | Inlet/outlet bend, wind value plate, cyclone, chute, pipa kolektor debu | |

| Sistem afterheat | Pipa separator lan tembok | |

| baja | Sistem pakan bahan mentah | Hopper, silo |

| Sistem Batching | Nyawiji bunker, nyawiji tong minyak, nyawiji disk, disk pelletizer | |

| Sistem transportasi bahan sintered | Hopper, silo | |

| Sistem Dedusting lan Ash discharge | Pipa dedusting, bend, y-piece | |

| Sistem coking | Coke hopper | |

| Pabrik kacepetan medium | Kerucut, buffle pemisah, pipa outlet, pipa batubara bubuk, kerucut pembakar | |

| gilingan bal | Klasifikasi, pemisah siklon, bend, cangkang jero konsentrator bubuk | |

| Daya termal | Sistem penanganan batubara | Mesin roda ember, hopper batubara, feeder batubara, orifice |

| Sistem ball mill | Pipa pemisah, siku lan kerucut, siku pabrik batu bara lan tabung lurus | |

| Pabrik kacepetan medium | badan pabrik batu bara, buffles pamisahan, conthong, pipa, sikut | |

| Pabrik tiba | Pipa lan sikut batubara sing digiling | |

| Sistem dedusting | Pipa lan sikut Dedusting | |

| Sistem pembuangan abu | Cangkang kipas, pipa | |

| Pelabuhan | Sistem transportasi bahan | Disk lan hopper mesin roda ember, hopper titik transfer, hopper unloader, |

| Peleburan | Sistem transportasi bahan | Measuring hopper, coke hopper, vibrating screen's chute, head valve, Intermediate bin, tail bin |

| Sistem Batching | batch hopper, nyawiji mesin | |

| Sistem pembakaran | Ember awu, tabung kalsin pompa, hopper | |

| Sistem dedusting | Pipa lan sikut Dedusting | |

| Kimia | Sistem transportasi bahan | Hopper, silo |

| Sistem dedusting | Pipa lan sikut Dedusting | |

| peralatan pangolahan | Vibromill liner | |

| Batu bara | Sistem penanganan batubara | Mesin roda ember, hopper batubara, feeder batubara |

| Sistem cuci batu bara | Hidrosiklon | |

| pertambangan | Sistem transportasi bahan | Hopper, silo |

Lembar Data Teknis

| S. Ora. | Atribut | Unit | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Kandungan alumina | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Kapadhetan | g/cc | ≥3.60 | ≥3.60 | > 3.65 | ≥4.2 |

| 3 | warna | - | Putih | Putih | Putih | Putih |

| 4 | Penyerapan banyu | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Kekuatan lentur | Mpa | 270 | 300 | 320 | 680 |

| 6 | Kapadhetan Moh | sasmita | 9 | 9 | 9 | 9 |

| 7 | Kekerasan Sumur Batu | HRA | 80 | 85 | 87 | 90 |

| 8 | Kekerasan Vickers (HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Ketangguhan Patah (Min) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Kekuwatan kompresif | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Koefisien Ekspansi Termal (25-1000ºC) | 1×10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Suhu operasi maksimum | ºC | 1450 | 1450 | 1500 | 1500 |

Tag produk

Tulis pesen sampeyan ing kene lan kirimake menyang kita